(844) 404-4588

24/7 Customer Support

24/7 Customer Support

| Brand: | USA Lab |

| Material: | 304 Stainless |

| Power Requirements: | 240V 16A 3Ph 5.5kW Explosion Proof Motor |

$70,300.00

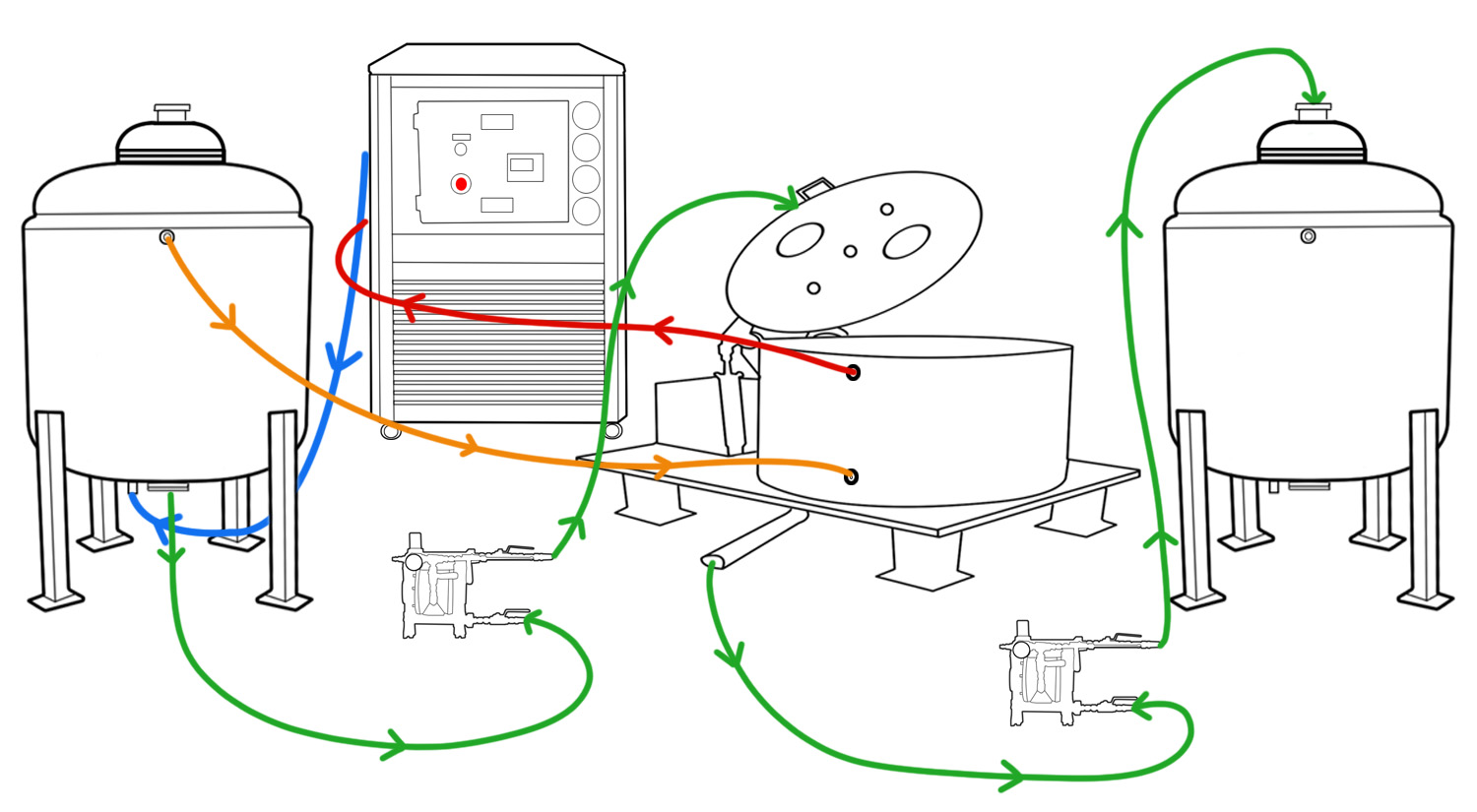

Our XTC-100-TK 100L Centrifuge turnkey system allows users the ability to extract botanical compounds to achieve superb results and separation while maintaining a closed-loop system. The XTC-100 system takes 60-100lbs of biomass and 60-90 gallons of ethanol per batch for approximately 960-1,500lbs of dry material per 8-hour shift with a single operator. The XTC system comes with two 300L storage vessels for ethanol pre-storage as well as ethanol mixture post storage.

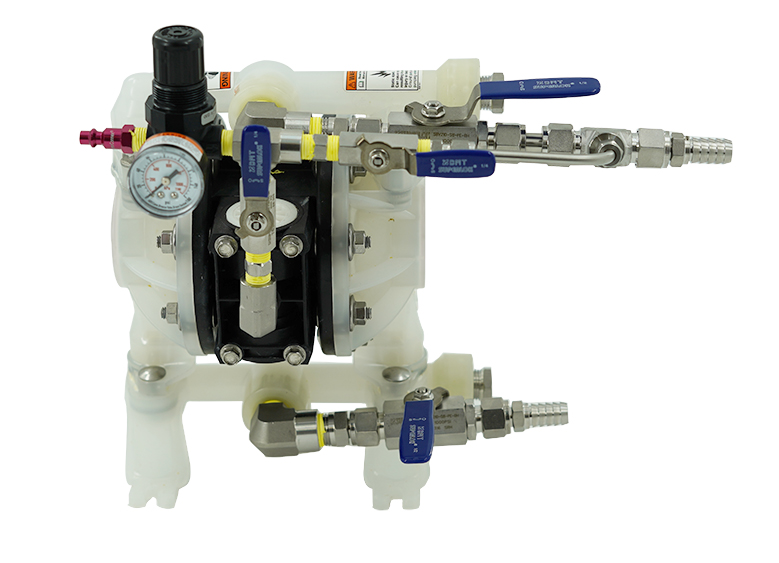

Each tank is fully jacketed and fully assembled to allow for fluids circulation with temperatures of up to -80°C, a 12” lid connection for numerous port connections, and a 6” bottom for ease of cleaning/draining. Fluid can transfer from each vessel via two diaphragm operated fluid pumps being operated by an air compressor. These pumps are easily operated and allow for up to 10 gallons per minute of fluid transfer. Each pump has a bypass which allows full line clear when the units are not in operation as well as easily adjustable air inlet, and inlet/outlet valves.

The XTC system also comes packed with one of USA Lab’s most advanced chillers, the CLC-100/80 100L -80°C chiller. This chiller can be run in tandem with the inlet ethanol storage tank that then is connected to the centrifuge jacket allowing for ultimate temperature control of the ethanol and mixture. The XTC-100-TK system is an easy-to-use turnkey ethanol extraction system that can fit into any lab setting with ease. This system fits in perfectly pre-filtration and recovery to act as a modular fit for a full system.

|

XTC-100L Turnkey Packing List |

|

|

ITEM |

QTY |

|

100L Jacketed Stainless Steel Centrifuge |

1 |

|

-80°C 100L Recirculating Chiller UC-100/80 |

1 |

|

USA Lab 300L Stainless Steel Jacketed Storage Vessel |

2 |

|

Hemispherical Reducer – Tri Clamp 6″ to 1/2 FNPT – S |

2 |

|

USA Lab 12″ Hemispherical Lid – 2x 2″ TC – 1x 3″ TC – 2x 1/2″ MNPT – 1x 1/4″ FNPT – 1X 3/8 MNPT |

2 |

|

ARO Diaphragm Fluid Transfer Pump, Kynar® Fully Assembled |

2 |

|

Superlok FNPT 210 Series Ball Valve – 1/2″ |

6 |

|

Superlok FNPT 210 Series Ball Valve – 3/8″ |

2 |

|

Glycerin Compound Gauge -1/4″ |

2 |

|

MNPT To Barb Adapter [ 1/2″ Barb x 1/2″ MNPT ] |

10 |

|

MNPT to FNPT Street Elbow [ 1/2″ X 1/2″ ] |

4 |

|

1/2″ Male Elbow NPT 90 Degrees |

2 |

|

MNPT To Barb Adapter [ 3/8″ Barb x 3/8″ MNPT ] |

2 |

|

Polycarbonate Sight Glass -[ 2″] |

4 |

|

Solid Tri Clamp End Cap [ 3″ ] |

2 |

|

Buna – 2″ |

4 |

|

Buna – 3″ |

2 |

|

Buna – 6″ |

2 |

|

Buna – 12″ |

2 |

|

SPTC – 2″ |

4 |

|

SPTC – 3″ |

2 |

|

SPTC 6- “ |

2 |

|

SPTC -12″ |

2 |

|

1/2 ” Silicone Hose Tubing – 10FT |

2 |

|

XTC-100 Specifications |

|

|

Material |

304 Stainless Steel |

|

Electrical |

240V 3Ph 5.5kW 16A |

|

Max RPM |

1200 rpm |

|

Max Plant Load |

60-100lbs |

|

Basket Volume |

100L |

|

Jacket Volume |

65L |

|

Lid Connections |

3x 1.5″ Tri-Clamp |

|

Jacket Connections |

2x 1.5″ Tri-Clamp |

|

Drain Connections |

3″ Tri-Clamp |

|

Gasket Material |

PTFE |

|

Lid Gasket Material |

Silicone |

|

Basket Inner Dimensions |

30.5″ Diameter x 17.8″ H |

|

Inner Dimensions |

38″ Diameter x 17.8″ H |

|

Exterior Dimensions |

70″ L x 48″ W x 48″ H |

|

Weight |

4000lbs |

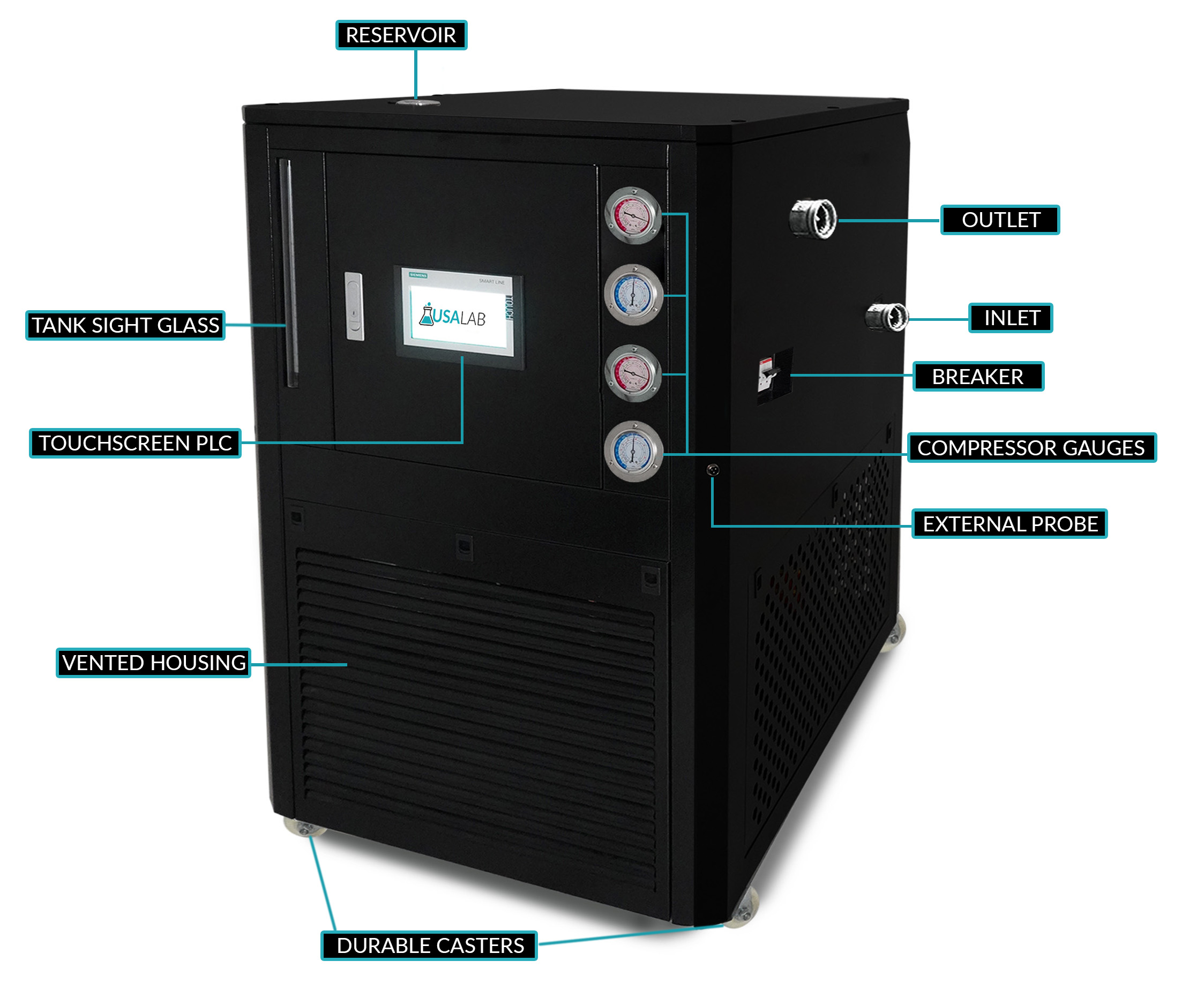

The USA Lab CLC-100/80 is a powerful -80°C Chiller with a 32L Expansion Tank. This unit is a true lab chiller that is ideal for applications involving vacuum systems, jacketed reactors, rotary evaporators, columns, solvent tanks, and even analytical instruments. This system is great for large 100L reactors and other large vessel.

The USA Lab CLC-100/80 chiller offers unbeatable performance, ease of use and high reliability. These units keep quiet despite having a powerful pump allowing for constant flow rates to match the needs of demanding applications.

This unit includes a Programmable Logic Controller (PLC).

A PLC will control whether the unit will cool depending on the programmed steps and cycles over time. The PLC also has an option for a static control to operate like a standard chiller.

Not For Consistent Heat Loads e.g. Falling Film, Butane Recovery.

|

CLC-100/80 FEATURES |

||

|

• Powerful chilling capacities and high BTU range. |

||

|

• High quality UL Listed compressor. |

||

|

• Touchscreen Siemens HMI display. |

||

|

• R404 refrigerant. |

||

|

• 12ft of tubing included with Tri-Clamp connections. |

||

|

• 1 Year warranty with US based parts and support. |

||

|

• Closed loop for higher thermal transfer performance. |

||

|

• Versatile Siemens PLC controller with external probe. |

||

|

SPECIFICATIONS |

||

|

Model |

CLC-100/80 |

|

|

Expansion Tank Capacity |

32L |

|

|

Tank Dimensions |

15.74″ x 7.87″ x 15.74″ |

|

|

Temperature Range |

RT to -80°C / -112°F |

|

|

Power Requirements |

200-240V 60Hz 41A Three Phase – Hardwired Only |

|

|

Control Type |

SIEMENS PLC S7-200 controller with external probe |

|

|

Refrigeration BTUs / Wattage |

150,000BTU – 1,250BTU / 44100-735W |

|

|

Total Power |

Nominal: 17kW / 41A | Peak: 31.2kW / 75A |

|

|

Plate Type Heating Area |

Heating exchanger surface area 2.50m2 x2 |

|

|

Compressor Type |

10HP Danfoss x 2pcs (UL Listed) |

|

|

Circulating Pump Wattage |

1500W (UL Listed) |

|

|

Fan Wattage |

280W x 3pcs |

|

|

Temperature Accuracy |

+/- 0.5°C (PT100) |

|

|

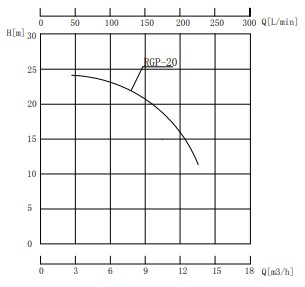

Pump Flow |

62 gpm (235L/Min) |

|

|

Lift |

78 ft (24 m) |

|

|

Pump Pressure |

34.8 psi (2.4 bar) |

|

|

Inlet / Outlet Size |

1.5″ FNPT with 1.5″ tri-clamp adapters |

|

|

Refrigerant |

R404 High Stage | R23 Low Stage |

|

|

External Dimensions |

58.7″ x 31.5″ x 56.7″ |

|

|

Weight |

860lbs |

|

|

Warranty |

1 Year |

|

|

PACKING LIST |

||

|

Model |

Quantity |

|

|

USA Lab CLC-100/80 Chiller |

1 |

|

|

Tri-Clamp Tubing |

12ft Total (2x 6ft) |

|

|

Manual |

1 |

|

Pump Curve:

|

300L-JSSR Specifications |

|

|

Material |

304 Stainless Steel |

|

Jacket Connections |

1/2″ FNPT |

|

Top Tri-Clamp Connection |

12″ Tri-Clamp |

|

Bottom Tri-Clamp Connection |

6″ Tri-Clamp |

|

Jacket Capacity |

32.4L |

|

Weight |

300lbs |

|

Caster Weight Limit |

440lbs per wheel (1760lbs total) |

|

Diameter – Outer Legs |

36″ |

|

Diameter – Outer Tank |

31″ |

|

Diameter – Inner Tank |

27″ |

|

Height – Total |

56″ |

|

Height – Tri-Clamp to Tri-Clamp |

37″ |

|

Height – Inner Vessel |

34″ |

|

Height – 6″ Tri-Clamp to Floor |

18″ |

*We recommend an Air Compressor with 8 CFM or more.*

|

ARO Specifications |

|

|

Item |

Double Diaphragm Pump |

|

Pump Operation Type |

Air Operated |

|

Max. Flow |

14 gpm |

|

Max. Temp – Pumps |

150°F |

|

Housing Material – Pumps |

Polypropylene |

|

Inlet / Outlet Size |

1/2″ |

|

Connection Style |

NPT |

|

Air Inlet Size |

1/4″ FNPT |

|

Diaphragm Material – Pumps |

Santoprene(R) |

|

Agency Compliance |

CE, REACH, RoHS |

|

Valve Type |

Ball |

|

Max. Operating Pressure |

100 psi |

|

Ball Material |

Santoprene(R) |

|

Check Seat Material |

Polypropylene |

|

Max. Dia. Solids |

3/32″ |

|

Manifold Connection |

Multiport |

|

Length |

13.75″ |

|

Width |

7.5″ |

|

Height |

11.625″ |

|

Self-Priming Dry |

10ft |

|

Self-Priming Wet |

15ft |

|

Manufacturer’s Warranty Length |

5 years |

|

Packing List for Assembled Pump |

|

|

ITEM |

QTY |

|

ARO 1/2 ” Diaphragm Pump |

1 |

|

Superlok Compression 210 Series Ball Valve -65ºC to 21ºC at 1000PSI [ 1/4″ ] |

1 |

|

Superlok Compression 210 Series Ball Valve -65ºC to 21ºC at 1000PSI [ 1/2″ ] |

2 |

|

Superlok FNPT 210 Series Ball Valve – 316SS -53ºC to 21ºC at 1000PSI [1/4″] |

1 |

|

FNPT x MNPT x MNPT 3-Way Street Tee [1/4″] |

1 |

|

MNPT to FNPT Street Elbow [1/4″ X 1/4″] |

1 |

|

MNPT x MNPT Hex Nipple Union [1/4″ x 1/4″] |

2 |

|

Superlok O.D. Tube X MNPT Connector – SMC [1/4″] |

1 |

|

Superlok MNPT Connector X O.D. Tube – SMA [ 1/2″ ] |

2 |

|

Superlok 1/2″ HB X 1/2″ TUBE STUB |

2 |

|

Superlok Compression Reducing Tee – SRUT [ 1/2″” X 1/4″ ] |

1 |

|

MNPT Hex Plug [1/2″] |

3 |

|

NORGREN Regulator,1/4 In |

1 |

|

GRAINGER Pressure Gauge |

1 |

|

ColorConnex Connector |

1 |

For Technical Support, Questions, or Other Issues Please Email or Call Us!

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.