(844) 404-4588

24/7 Customer Support

24/7 Customer Support

Soft gelatin encapsulation line is suitable for filling a certain amounts of prepared medicine solutions into two lines gelatin sheet and forming soft gelatin capsules or balls with various size, shape and color after compression under the action of one pair opposite movable moulds.

Some of the shapes that you can make using the softgel encapsulation machine are:

* Oblong Softgel Capsules

* Round Softgel Capsules

* Tube Softgel Capsules

* Oval Softgel capsules

The sizing of the softgel capsules also vary from 000 which is the biggest to size 5 which is the smallest.

Soft gelatin encapsulation line is suitable for filling a certain amounts of prepared medicine solutions into two lines gelatin sheet and forming soft gelatin capsules or balls with various size, shape and color after compression under the action of one pair opposite movable moulds.

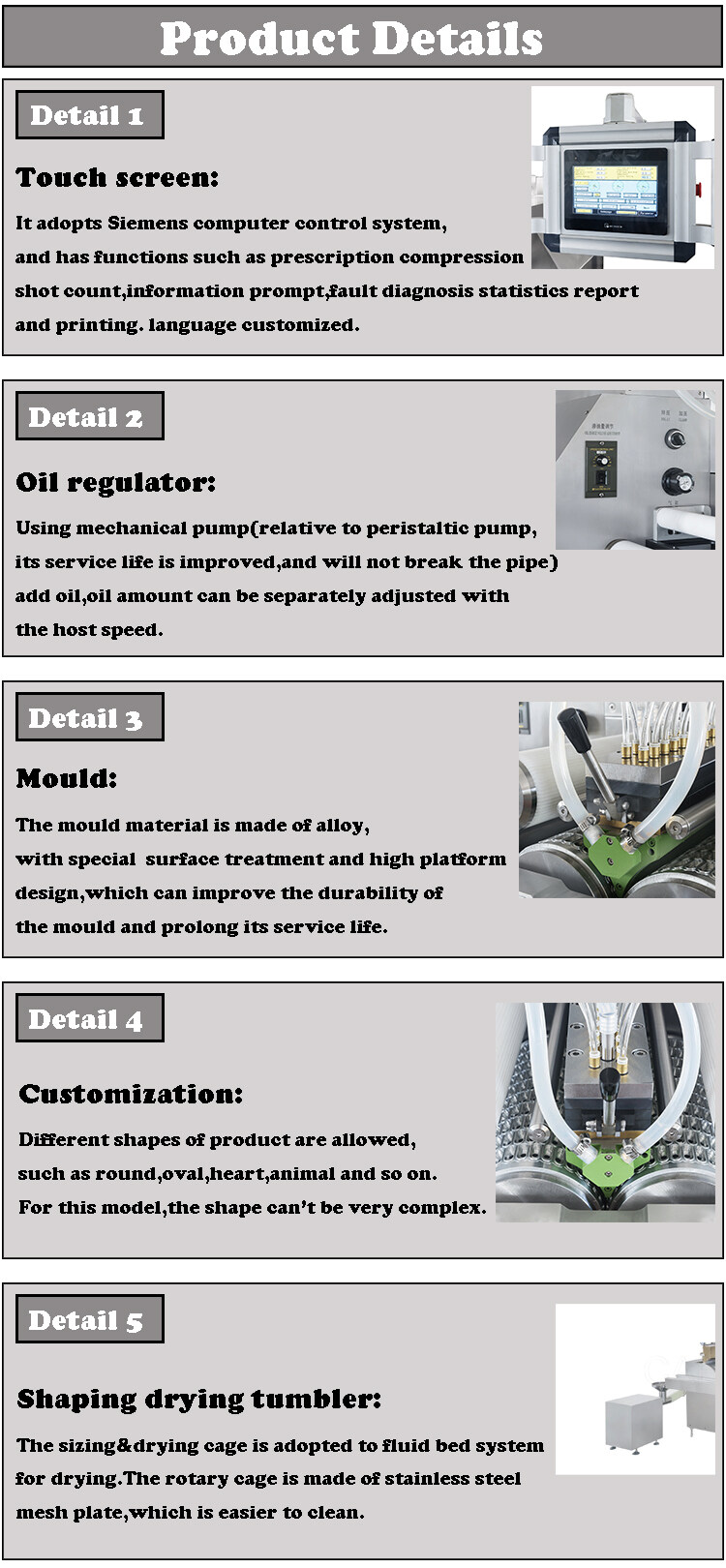

It’s consist of compression system, gelatin melting system, raw material compounding system, shaping and drying system, cleaning system, recycling system etc. During gelatin compression and forming, it can be finalized within the sealed cavity so as to avoid coming across medicine oxygenation. All material contact parts are made of S.S. 316L in full compliance with “GMP” standard requirements.

| Die Roll Capacity In Common Use | |||||||||||

| RJWJ-115 | RJWJ-200 | RJWJ-300 | |||||||||

| Shape | Model | Mould cavity | Capacity of the medium speed(Pill/Hour) | Shape | Model | Mould cavity | Capacity of the medium speed(Pill/Hour) | Shape | Model | Mould cavity | Capacity of the medium speed(Pill/Hour) |

| Oval | 4 | 114 | 17100 | Oval | 4 | 286 | 51480 | Oval | 4 | 714 | 85680 |

| 8 | 85 | 12750 | 8 | 230 | 41400 | 8 | 585 | 70200 | |||

| 20 | 52 | 7800 | 20 | 140 | 25200 | 20 | 334 | 40080 | |||

| Oblong | 4 | 86 | 12900 | Oblong | 4 | 236 | 41400 | Oblong | 4 | 554 | 66480 |

| 8 | 64 | 9600 | 8 | 206 | 37080 | 8 | 468 | 56160 | |||

| 20 | 48 | 7200 | 20 | 138 | 24840 | 20 | 315 | 37800 | |||

| Round | 8 | 82 | 12450 | Round | 8 | 231 | 41580 | Round | 8 | 590 | 70800 |

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.