(844) 404-4588

24/7 Customer Support

24/7 Customer Support

| Brand: | USA Lab |

| Material Capacity: | 10-20 lbs |

| Solvent Tank: | ASME Certified |

| Solvent Tank Capacity: | 200lb (96lb Butane) |

$17,499.00 – $38,000.00

The TRU series is our way of bringing back quality, reliability, and accurate systems back to the market. The TRU series is all about maximizing your efficiency for every run. Equipped with 2 (6″ x 48”) spools that truly fits +10lbs of material, an IRC with a 5 micron sintered disk, ASME certified solvent tank, and to top it off it is completely fitted with Superlok compression fittings and valves. Upgrade to the 10LB TRU closed loop system today and see the USA Lab Difference!

Process up to 65lbs of material in an 8 hour day with recovery pump

*Systems may have a lead time of 1-2 weeks*

| FEATURES | ||

| • The material columns are 6″x48″ with sight glasses to allow for viewing of up to 10lbs of milled material. | ||

| • The CRC is 6″x12″ and comes with a 5 micron sintered disc and sight glasses for clear viewing of the process. | ||

| • The CRC has a built in bypass to allow easy bypass of the CRC. | ||

| • The collection is an 8″x36″ and 8″x12″ jacketed spool which allows for easy heating and quick cleaning. | ||

| • The 3″x 18″ sieve and 10″x10″ coil allow for fast and easy recovery of solvent. | ||

| • Large rack mounted footprint of 74″ x 24″ x 66″. | ||

| • High quality 1/2″ Compression fittings. | ||

| • Each vessel has a 1/4″ MJIC Line for connecting nitrogen lines. | ||

| • 150psi Cryogenic Pressure relief valves for safe operation. | ||

| SPECIFICATIONS | ||

| Model | 10LB-TRU | |

| Max Material | 10LB Trim | 20LB of milled material | |

| Material Column Size | 2 x 6″ x 48″ | |

| CRC Size | 6″ x 12″ 5UM | |

| Sieve Size | 3″ x 18″ | |

| Coil Size | 10″ x 10″ Bucket | |

| Solvent Tank Size | 200LB | 96 lb of Butane | |

| Collection Tank Size | 8″ x 48″ | 37.42 Liters | |

| Foot print | 74″ x 24″ x 66″ | |

| Weight | 550lbs | |

| PACKING LIST | ||

| Model | Quantity | |

| 200LB ASME Solvent Tank | 1 | |

| 8″ x 48″ Collection Tank | 1 | |

| 6″x 48″ Material Column | 2 | |

| 6″ x 12″ CRC with 5 Micron Disc | 1 | |

| 3″ x 18″ Sieve | 1 | |

| 10″ x 10″ Condensing Coil | 1 | |

| 39″ x 30″ x 59″ Aluminum Rack | 1 | |

|

Turnkey Packing List |

|

|

Model |

QTY |

|

TRU-10lb System |

1 |

|

UL Listed 21CFM UVP-21 Corrosion Resistant 2-Stage Vacuum Pump |

1 |

|

30L 200°C 6KW or 3KW Closed Loop Heater CRH-30L |

1 |

|

40ºC 50L Closed Loop Recirculating Chiller CLC-50/40 |

1 |

|

Master Vapor Pump 6CFM Recovery Pump (Included in Active System) |

1 |

This product is mechanically cooled by a high-performance scroll compressor. The CLC Series differs by offering a faster way to transfer the thermal load. Instead of cooling passively. Our CLCs use heat exchangers to cool the fluid in line. Allowing for less loss and more ease of use.

Similarly to the UC Series, our CLC Series are compatible with all of your most demanding equipment. Contact us to today if you have more questions about our newest line of high-performance chillers.

*This product is tested before we ship it out. Please allow for a lead time of 1-3 business days.*

|

CLC-50/40 SPECIFICATIONS |

||

|

Model |

CLC-50/40 |

|

|

Usage Temperature Range |

-40°C to Room temperature (40°C/70°F) |

|

|

Environment Temperature |

5°C to 40°C |

|

|

Environment Humidity |

≤70%RH |

|

|

Power Supply |

Single phase 220V-240V/60HZ |

|

|

Safety Protection |

Delay, overcurrent, overheating, phase sequence, phase loss protection |

|

|

Display |

LCD display, key operation |

|

|

Temperature Control Accuracy |

±0.1℃ |

|

|

Sensor |

PT100 |

|

|

Total power |

4035W |

|

|

|

Specification |

5HP |

|

|

Quantity |

1 |

|

Compressor |

Power |

3675W |

|

|

Cooling capacity |

7569W-3640W |

|

|

Power |

100W |

|

|

Lift |

4-6M |

|

Circulation Pump |

Flow |

20-40L/min |

|

|

Pressure |

≤0.4bar |

|

|

Power |

260W |

|

Air-Cooling Condenser |

Heating exchange area |

21.2㎡ |

|

|

Air volume |

3400m³/h |

|

Refrigerant |

R404A |

|

|

Plate-Type Heat Exchanger |

Heating exchange area 1.46m2 |

|

|

Equipment Material |

Cold plate spray, anti-corrosion |

|

|

Storage Tank Volume |

~11L (300X300X120mm) |

|

|

Outer Circulation Interface |

Pagoda joint with Φ16mm outer diameter (facing the left side of the equipment) |

|

|

Overall Dimension (W*D*H) |

670×730×1100 mm |

|

|

Packing Dimension |

840×790×1290mm wooden package 0.86m³ |

|

|

Net Weight |

124KG / 280lbs |

|

|

Packing Weight |

178KG / 400lbs |

|

The USA Lab CRH heater is a powerful 200°C heater with a 20L Closed Loop Reservoir. Our CRH heater comes with three individual heating elements, and a strong positive displacement pump for constant flow and high performance. The closed loop reservoir allows for higher thermal transfer performance than open loop heaters, and provides superior heating capabilities. This unit is a true lab heater that is ideal for applications involving vacuum systems, jacketed reactors, columns, solvent tanks, and even analytical instruments. This system is great for larger columns, tanks, and high heat applications.

The USA Lab CRH heater offers unbeatable performance, ease of use and high reliability. These closed loop heaters are the best on the market for demanding applications and precision heating.

|

CRH-30 FEATURES |

||

|

• Powerful high wattage heating at 200°C. |

||

|

• Easy to read LCD digital display. |

||

|

• Individual heating elements. |

||

|

• Strong positive displacement pump. |

||

|

• 12ft of insulated tubing included. |

||

|

• 1 Year warranty with US based parts and support. |

||

|

• Closed loop for higher thermal transfer performance. |

||

|

|

|

|

|

SPECIFICATIONS |

||

|

Model |

CRH-30 3KW |

CRH-30 6KW |

|

Oil Tank Capacity |

20L |

|

|

Oil Tank Dimensions |

390 x 280 x 180mm |

|

|

Temperature Range |

RT to 200°C |

|

|

Power Requirements |

220-240V 50-60hz 15A Single Phase 6-20P Plug |

220-240V 50-60hz 28A Single Phase 6-30P Plug |

|

Control Type |

LCD Digital Display |

|

|

Heating BTUs / Wattage |

10236 BTU / 3000W |

20472 BTU / 6000W |

|

Total Power |

3250W / 15A |

6250W / 28A |

|

Circulating Pump Wattage |

250W |

|

|

Temperature Accuracy |

+/- 1°C |

|

|

Pump Flow |

15L/Min |

|

|

Lift |

20m |

|

|

Inlet / Outlet Size |

1/2″ MNPT |

|

|

External Dimensions |

25.6″ x 18.1″ x 36.8″ |

|

|

Weight |

116lbs |

|

|

Warranty |

1 Year |

|

|

|

|

|

|

PACKING LIST |

||

|

Model |

Quantity |

|

|

USA Lab CRH-30 Heater |

1 |

|

|

1/2″ FNPT Insulating Tubing – 6ft |

2 |

|

|

Manual |

1 |

|

| SPECIFICATIONS | |||

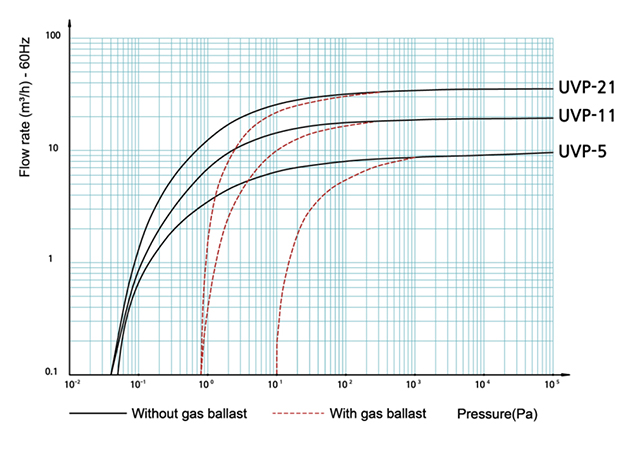

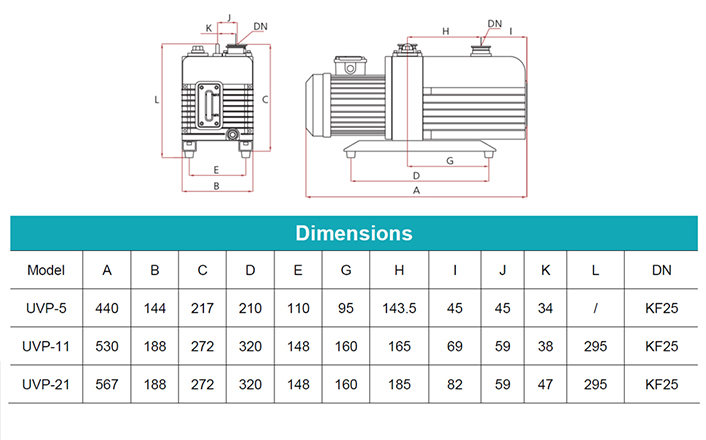

| Model | UVP-5 | UVP-11 | UVP-21 |

| Pumping Speed(60Hz) | 5.5 cfm | 11 cfm | 21 cfm |

| Ultimate total pressure gas ballast close |

4×10-2 Pa (3.0×10-4 torr) 0.3 Micron |

||

| Ultimate total pressure gas ballast open |

8×10-1 Pa (6×10-3 torr) 6 Micron |

||

| Power supply | 1 Phase (110V, 60Hz) | ||

| Power rating(kW) | 0.4 | 0.75 | 1.1 |

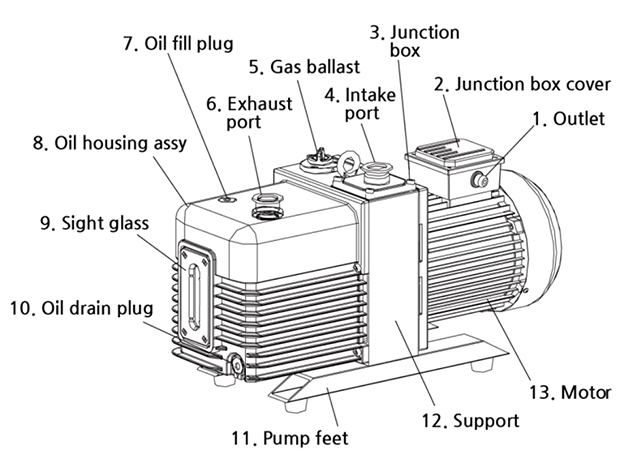

| Inlet/Exhaust Flange | KF 25 | ||

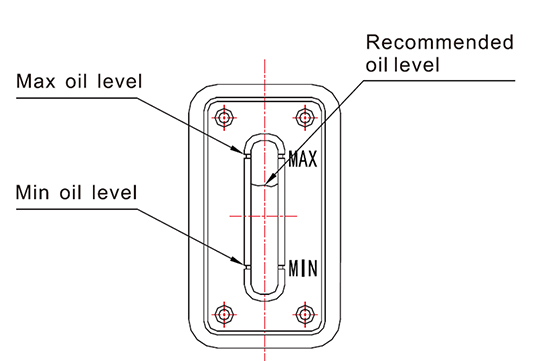

| Oil capacity(L) | 0.6~1.0 | 0.9~1.5 | 1.3~2.0 |

| Ambient temperature(℃) | 10~40℃ | ||

| Noise level(dB) | ≤56 | ≤60 | ≤60 |

| Weight(kg) | 21 | 30 | 43 |

| External Dimensions | 440x144x217MM 17.3×5.6×8.5″ |

530x188x272MM 20.8×7.4×10.7″ |

567x188x272MM 22.3×7.4×10.7″ |

| Certification | UL | ||

| Warranty | 2 Year | ||

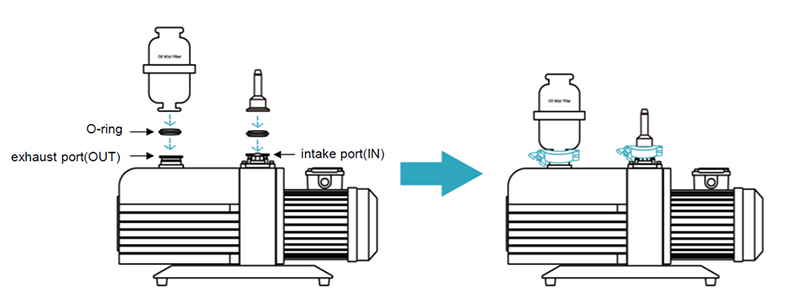

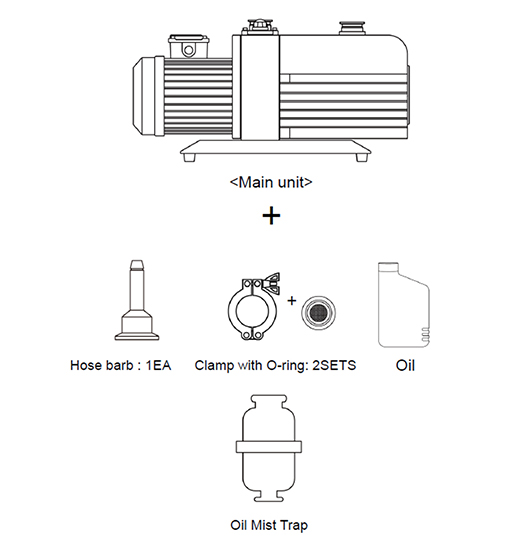

| PACKING LIST | |||

| Model | UVP-5 | UVP-11 | UVP-21 |

| Main Vacuum Pump | 1 | 1 | 1 |

| KF25 x 3/8″ Barb | 1 | 1 | 1 |

| KF25 Clamp | 2 | 2 | 2 |

| KF25 O-ring | 2 | 2 | 2 |

| Oil Mist Trap | 1 | 1 | 1 |

| Quart of Oil | 1 | 1 | 1 |

| Manual | 1 | 1 | 1 |

Mastor Vapor Pumps MVP-6CFM Vapor Recovery Pump can recover a staggering 1lb of vapor per minute. Each system is certified and made in the USA for superior quality. This pump is 3rd party certifiable with your system, UL listed and FDA compliant. The pump uses no oil allowing for zero contamination of your product.

You can run these pumps with 100% duty cycle, 24/7 without overheating or issue. The dual-diaphragm pump is electrically powered by an explosion-proof motor, and has a working pressure of 350psi.

Performance Factoids:

Pump Head Charge:

Electrical and Mechanical:

Documents:

For Technical Support, Questions, or Other Issues Please Email or Call Us!

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.