(844) 404-4588

24/7 Customer Support

24/7 Customer Support

$17,165.00 – $19,115.00

Ultrasonic homogenizers, the modern version of “mortar and pestle”, they can disrupt tissues and cells through cavitation and ultrasonic waves. Basically, an ultrasonic homogenizer has a tip which very rapidly vibrates, causing bubbles in the surrounding solution to rapidly form and collapse. This creates shear and shock waves which tear apart cells and particles.

Ultrasonic Homogenizers are recommended for homogenization and lysis of laboratory samples that do not require traditional grinding or rotor-stator cutting techniques for processing. Small and large ultrasonic probes are used in a variety of sample volumes to be processed. A solid probe allows for less chance of sample loss and cross-contamination between samples.

Sonication is the act of applying sound energy to agitate particles in a sample, for various purposes. Ultrasonic frequencies (around 20 kHz) are usually used, leading to the process also being known as ultrasonication or ultra-sonication. In the laboratory, it is usually applied using an ultrasonic bath or an ultrasonic probe, colloquially known as a sonifier.

Sonication can be used for the production of nanoparticles, such as nanoemulsions, nanocrystals, liposomes and wax emulsions, as well as for wastewater purification, degassing, extraction of plant oil, extraction of anthocyanins and antioxidants, production of biofuels, crude oil desulphurization, cell disruption, polymer and epoxy processing, adhesive thinning, and many other processes. Sonication is also commonly used in nanotechnology for evenly dispersing nanoparticles in liquids.

LSP-600 in Continuous Flow-Through Mode

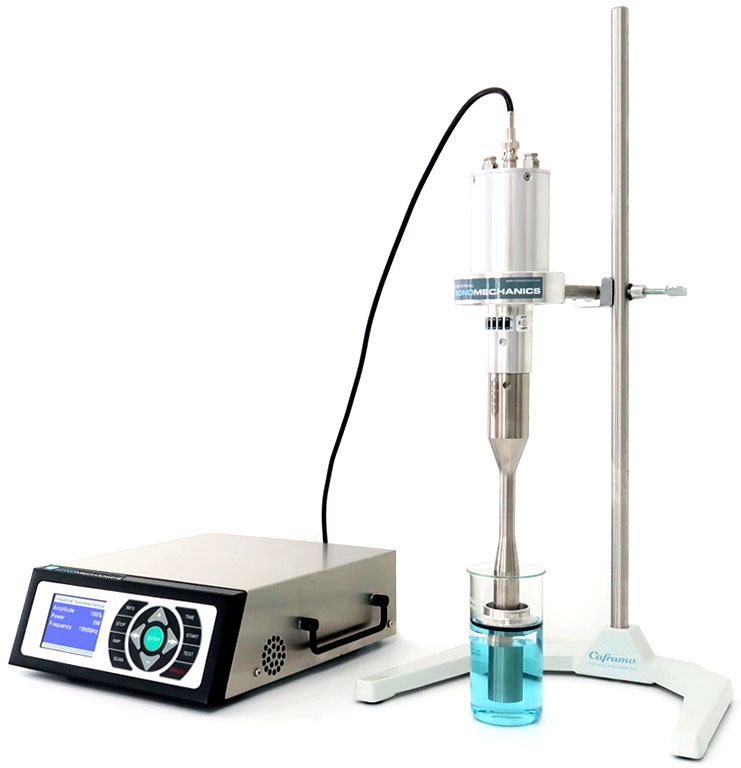

The LSP-600 600 watts bench-scale ultrasonic liquid processor from Industrial SonoMechanics

Features

LSP-600 in Batch Mode

| Model | LSP-600 |

| Electrical requirements |

100V-120V (20A max.), 220V-240V (10A max.), 50/60Hz |

| Ultrasonic output | 1000 V rms (max.), 20 (+/- 1) kHz, 600 W (max.) |

| Air-cooled piezoelectric transducer (ACT-22-LSP) |

Output Characteristics: amplitude 22 microns (max.), frequency 20 (+/- 1) kHz, power 600 W (max.) |

| Full-wave Barbell Horn (FBH, 21 mm tip diameter) |

Output characteristics: amplitude 115 microns (max.), frequency 20 (+/- 1) kHz, power 600 W (max.) |

| Materials of wetted parts |

Reactor chamber 304 stainless steel. Food compatible. Horns (FBH, CH, microtips) Grade 5 Titanium (Ti6Al4V). Food compatible. Gaskets Buna-N or Teflon. Food compatible. O-rings Buna-N. Food compatible. |

| Noise level |

103 – 106 dBa at 2′ away. Noise reducing earmuffs or sound enclosure required. |

| Capacity |

15 ml – 100 ml with CH (batch mode) 100 ml – 500 ml with FBH (batch mode) 500 ml – 1 L with FBH + reactor chamber (flow-through mode). |

| Productivity rates | Productivity rates are highly dependent on the nature of each process and range from about 200 mL/h for challenging tasks (e.g., top-down nanocrystallization of active pharmaceutical compounds) to over 10 L/h for fast processes (e.g., degassing, deagglomeration). |

| Optional accessories |

Flow-through reactor chamber (flow cell, 1/2″ tri-clamp inlet and outlet, cooling jacket) Conventional horn (CH, 12.7 mm tip diameter, amplitude 113 microns (max.)) Support stand with clamp holders Noise reduction ear muffs |

| Warranty | One year |

| Download | User Manual, Assembly Guide |

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.