(844) 404-4588

24/7 Customer Support

24/7 Customer Support

The line of semi-automatic auger fillers is the ultimate in operator convenience. The innovative design and PLC-based controls make each filler an affordable, reliable auger filler with the same rugged construction.

The line of semi-automatic auger fillers is the ultimate in operator convenience. The innovative design and PLC-based controls make each filler an affordable, reliable auger filler with the same rugged construction.

It is the ultimate in operator convenience – precision engineered for time saving, cost cutting performance.

| Model | HZSL-B |

|---|---|

| Feeding height | 1600mm |

| Volume | 120L |

| Voltage | AC220V, 50/60HZ |

| Power | 1.8KW |

| Dimensions | 2200mm*900mm*2050mm |

| Machine package dimensions | 1140mm*1030mm*1180mm |

| Feeder package dimensions | 2450mm*240mm*500mm |

| Machine package weight | 147kg |

| Feeder package weight | 40kg |

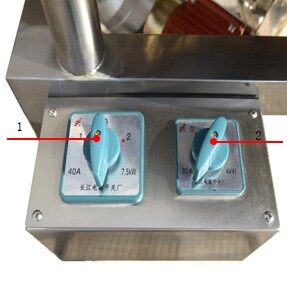

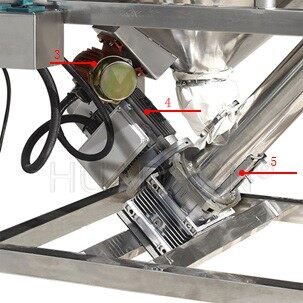

| 1.Forward/reverse switch | 2.Vibration switch | 3.Vibration motor |

| 4.Feeding motor | 5.Discharge port | 6.Bearing cap |

| 7.Outlet | 8.Spiral duct | 9.Storage bin |

| Note: “1” in the forward/reverse switch indicates forward rotation and loading; “2” indicates reverse rotation and clearing. | ||

Make sure the machine is in good condition before installation, all parts are complete and no damage.

Place the device on a level, level floor, easy to maintain and repair, and secure the device.

Check the power supply to make sure it is consistent with the power used by the machine.

Check the screw feeder to ensure that there are no foreign objects in the screw feeder.

Press the forward/reverse switch to “1”, and load the machine to check whether the motor steering is the same as the mark steering. If it is different, turn it to “2”.

First check if the switch is in the initial position.

Turn on the power.

The forward/reverse switch is turned to “1” and loaded.

Put the raw materials to be transported into the storage bin.

Monitor the operation of the machine.

After the raw material is delivered, the forward/reverse switch is turned to “0” and the machine stops running.

When the machine is installed, the center line of each spiral section is different, so that when it is running, the machine will be eccentric and the outer casing will sway. Need to reinstall and find the centerline, so the machine will be stable

There is a hard block or small iron block mixed in the conveying material of the screw feeder, the reamer is stuck, the motor is overloaded, and the motor is burned. The small iron block should be prevented from entering and the reamer and the casing should be kept at a certain gap.

When the screw feeder is installed, the center line of each screw is not the same. Please re-install the center line or replace the screw.

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.