(844) 404-4588

24/7 Customer Support

24/7 Customer Support

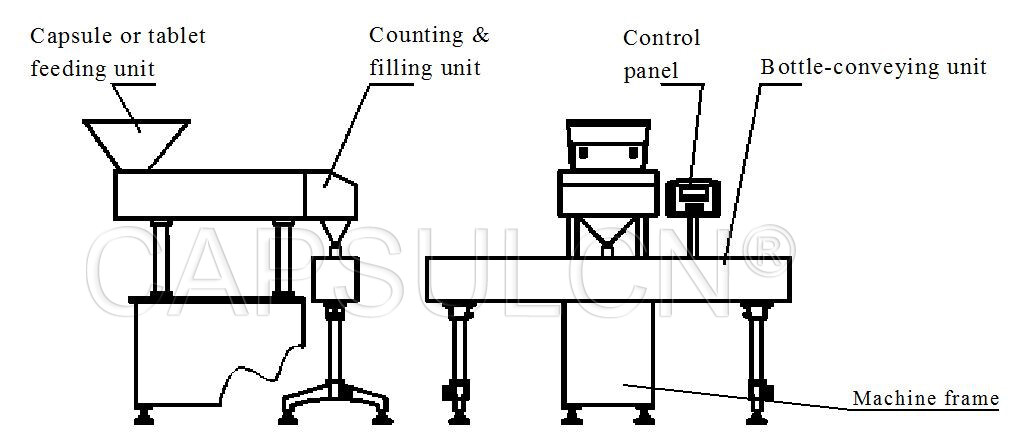

This machine is a intelligent automatic counting and filling machine, which is widely applied for capsule counting for big scale production in hospital, pharmaceutical factory etc.

This machine is a intelligent automatic counting and filling machine, which is widely applied for capsule counting for big scale production in hospital, pharmaceutical factory etc.

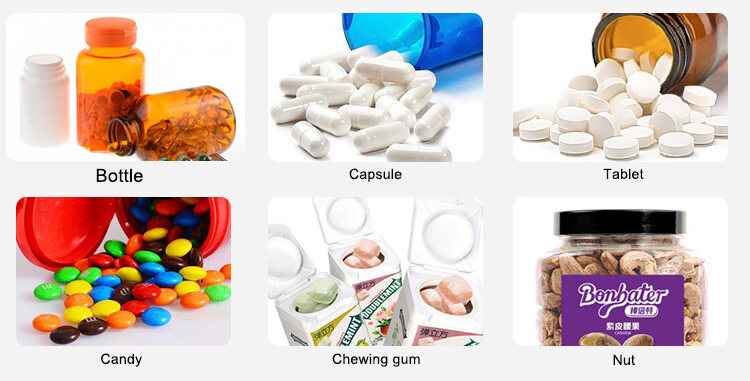

The machine can count & fill different shapes or size of products accurately like soft gel capsules, hard capsules, tablets, sugar coating, and film coating tablets, pills, herb medicine or similar products into containers or vials.

High speed PLC system controls the whole process including counting, filling and monitoring. The machine counts precisely, quickly. Put bottle by conveyer belt and fill automatically, high differentiate rate, fast responding speed.

Some accessory equipments can be connected like feeding turntable, capping machine and Labeling machine and so on.

Main features:

| Model | PBDS-8 | PBDS-12 | PBDS-16 | PBDS-24 |

|---|---|---|---|---|

| Production capacity | 10~50 bottles per minute | 20~55 bottles per minute | 60-100 bottles per minute | 80-150 bottles per minute |

| Container size | Dia.:20~100mm Height:50-100mm |

Dia.:20~100mm Height:40~200mm |

Dia.:20~100mm Height:40~220mm |

Dia.:20~100mm Height:40~220mm |

| Size of capsule/tablet | Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

| Main Power | 0.4kw | 1.5kw | 1.5kw | 1.7kw |

| Power Supply | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz |

| Weight | 280kg | 300kg | 360kg | 580kg |

| Overall Dimensions | 1600x1500x1600mm | 1600x1500x1600mm | 2600x1600x1600mm | 4200x1800x1600mm |

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.