(844) 404-4588

24/7 Customer Support

24/7 Customer Support

The double cone mixer is a kind of equipment for mixing dry powder or dry granular materials, which is suitable for pharmaceutical industry, chemical industry, food, agriculture and other industries.

$5,999.00

The machine is suitable for mixing dry, powdery, granular materials and irregular materials in pharmaceutical, chemical and food products.

The double cone mixer is a kind of equipment for mixing dry powder or dry granular materials, which is suitable for pharmaceutical industry, chemical industry, food, agriculture and other industries.

The double cone mixer has a unique structure design. The mixing container rotates. During this process, the materials in the container move in all directions, which makes the materials in the container be mixed more, with good effect and high mixing uniformity. The maximum load coefficient is 0.7.

The rotation axis of the double cone mixer deviates an angle from the center of the mixing container during mixing. When the container rotates, the material diffuses, flows and moves tangentially. In this way, under the action of frequent and rapid rotation and turning, the mixed materials are mixed with each other, which ensures that the materials can meet the ideal mixing requirements in a short time.

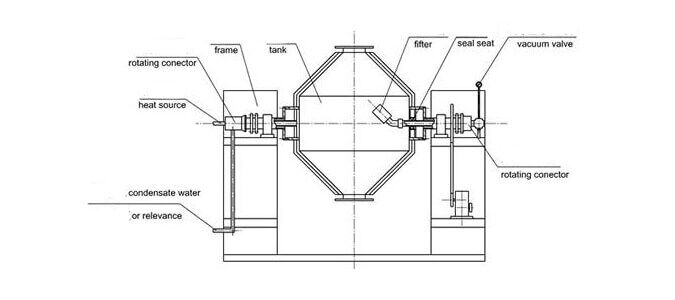

Structure:

The double cone mixer is composed of the machine frame, drive system, the mixing container, electrical control system and other components.

● Machine frame: it is composed of structural parts and stainless-steel panel, with drive system and the electrical control system inside.

● Drive system: it consists of the belt, speed reducer, chain wheel and other drive mechanisms.

● Mixing container: Double-cone special structure is made of high-quality stainless steel. Its internal and external surfaces have been polished and are easy to clean, which conforms to GMP requirements. The material discharging is controlled by the butterfly valve. The material is discharged smoothly under the action of gravity, without accumulation and cross contamination.

● Electrical control system: See the Electrical Schematic Diagram.

| Model | W-300 | W-500 | W-1000 | W-2000 | |

|---|---|---|---|---|---|

| Volume | 300L | 500L | 1000L | 2000L | |

| Mixing speed | 3-12Rpm/min | ||||

| Maximum mixing amount | 150kg | 250kg | 500kg | 1000kg | |

| Weight | 500kg | 800kg | 1200kg | 2000kg | |

| Total power | 2.2KW | 3KW | 4KW | 7.5KW | |

| Dimensions | 1685×900×1300mm | 1910×1220×1950mm | 2765×1650×2200mm | 3100×1900×2550mm | |

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.