(844) 404-4588

24/7 Customer Support

24/7 Customer Support

Repackaging many kinds items, use multiple spiral packing weighing, work more evenly in the process BuKa material, but with various membrane unit work, using infrared reflection principle, induction block feeding, more convenient to operate.

$379.00

Repackaging many kinds items, use multiple spiral packing weighing, work more evenly in the process BuKa material, but with various membrane unit work, using infrared reflection principle, induction block feeding, more convenient to operate.In addition the machine adopts the multi-function packer heightening version can be separated into two different 2 – 100 grams, between grams can be arbitrary regulation.About 15 minute package – 20, precision around 0.2 g, depending on different items.

This machine is widely used in: All kinds of powder, tea, grain, grain, medicinal herbs, seeds, spices, monosodium glutamate, sesame seeds, salt, beans, rice, chemical raw materials, electronic components, hardware components, and so on.

| Model | FZX-1 | FZX-2 |

|---|---|---|

| Filling Weight | 1-50g | 1-100g |

| Deviation | ±0.2g | ±0.2g |

| Scope | Irregular/Granule/Powder | Irregular/Granule/Powder |

| Speed | 15-35 bags/Min | 15-35 bags/Min |

| Precision | 0.1-0.2g(basis on different material) | 0.1-0.2g(basis on different material) |

| Bottle height | 30-300(MM) | 30-300(MM) |

| Bottle Dia. | 30-500(MM) | 30-500(MM) |

| Voltage | 220V 50HZ/110V 60HZ | 220V 50HZ/110V 60HZ |

| Power | 50W | 50W |

| Dimension(L x W x H) | 45x43x48CM | 45x43x64CM |

| Net Weight(kg) | 27.5kg | 27.5kg |

| 1.Hopper | 2.Control panel | 3.Viewing port |

| 4.Body | 5.Outlet |

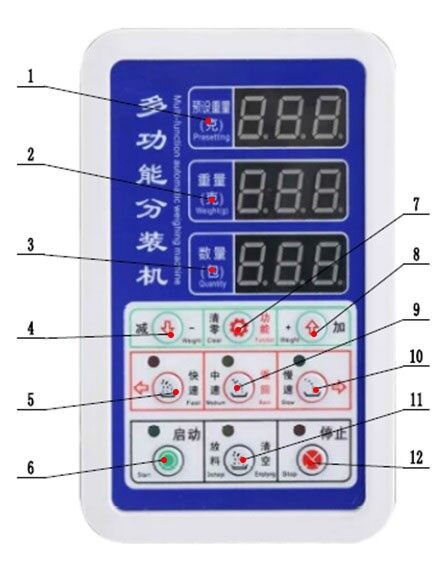

| 1.Preset weight | 2.Weight | 3.Quantity | 4.Minus button |

| 5.Quick button | 6.Start button | 7.Zero button | 8.Plus button |

| 9.Medium speed button | 10.Slow button | 11.Clear button | 12.Stop button |

Before using the new machine, please find the shipping safety screw with the mark on the bottom plate and remove it with the tool. The machine can operate normally.

Plug in the power, turn on the power switch on the side of the machine, the computer control panel lights up, the machine emits a “di~~” sound, press the Clear button, the machine will automatically return to zero and enter the standby state.

In order to avoid injury and loss to you and others, please be sure to observe the following safety precautions.

When the machine just starts, replaces or reselects the dispensing speed, the first few packages may have an error value of more than 0.2 g. That is the computer is testing your pellet quality, please don’t worry. Occasionally, the overweight phenomenon in the packaging process may be that there are too large particles in your particles. Please pick out the coarse particles and adjust the dispensing speed of different particles.

If the sound is too loud when the equipment is to work, please confirm whether the bottom safety screw of the Spiral Filling Machine has been removed, and whether the work table placed on the equipment is flat and tough (Note: the instability of the workbench will affect the accuracy of the equipment).

Check that the machine or work surface is placed flat or close to other electrical equipment that can generate vibration.

In the work, if there is material shortage or blockage, the machine will emit a “di, di, di” alarm sound, and the machine will stop working and enter the standby state. Please check the storage capacity. If the material is missing, please add and continue to pack; if it is blocked, your particles may be too long or wet, causing the inlet to be blocked. Please open the inspection port at the top of the machine and clean the blockage and replace it and repack it.

Our team of professionals is dedicated to supplying the highest quality and safest products in the industry. We look forward to working with you and your team in the future. If you have any questions or comments you may email us at sales@scisolinc.com or call us at (844) 404-4588.